I have been playing with different amounts of blue and have fixed on 1 g of blue for 240 ml of total pu (180 ml pu +60 ml hardener)

Author: Mishmi Takin

Mould making disaster

We did some mould making yesterday who h was a bit of a disaster with the polyurethane positives. We didn’t put mold release and probably left it for too long. The positives didn’t come out from the mould. We could salvage only half.

We also lost a few mould because I stupidly pushed everything while opening the catalyst ( I think) and tried to fix it by random movement pair pouring silicone

This silicone had a fruity ester type smell. The catalyst smells of homeopathic medicine. and the silicone doesnt seem to give out formaldehyde after polymerization.

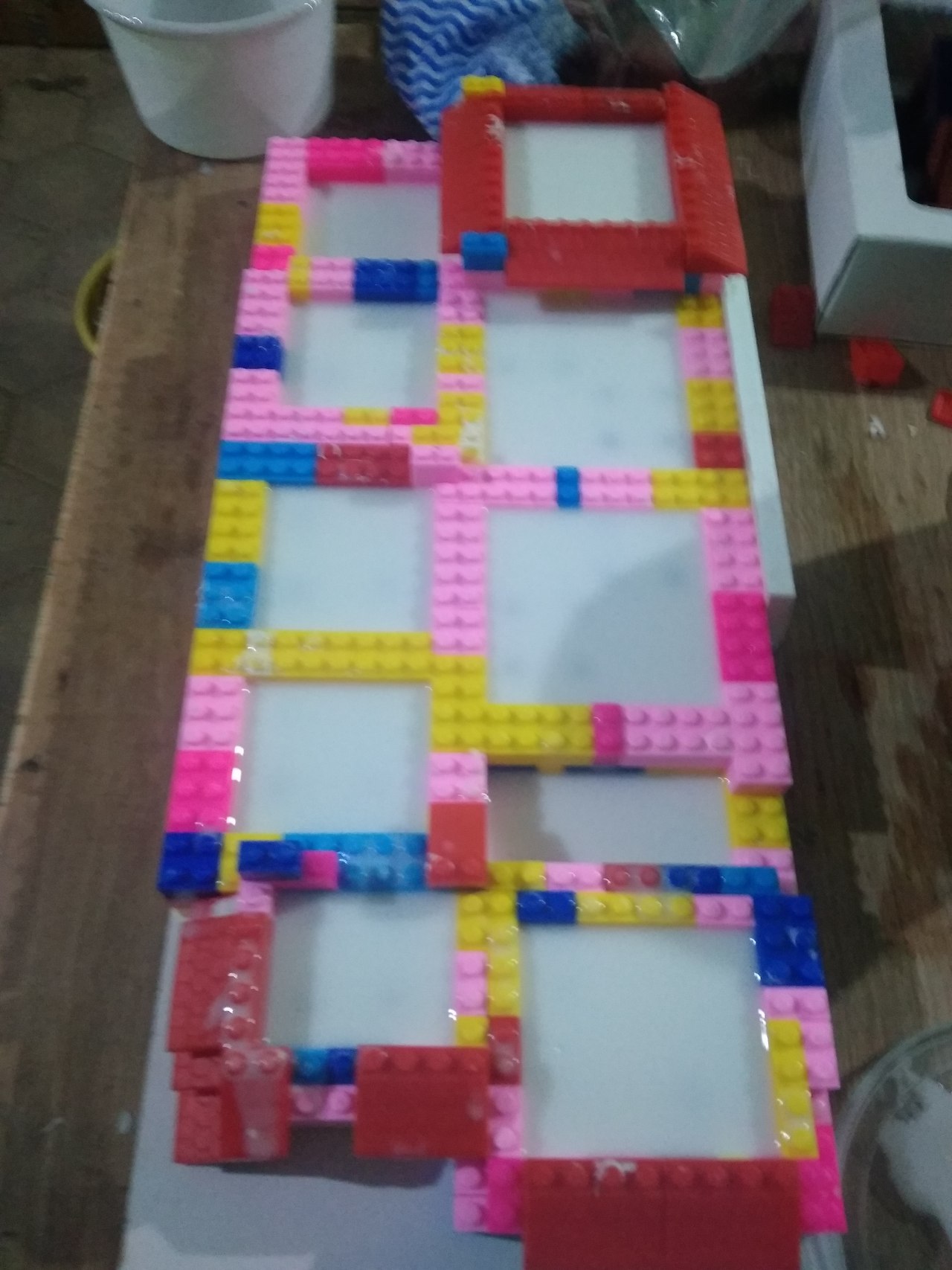

Design of the tiles

Sud got the entire tile set printed and made a jig for pasting with pvc glue on the backs of the tiles.

Base tiles

Sud had an eventful day too at printxpress. Those are the grids and he also got the tiles printed. 🙂 It looks so awesome. I want one of those Ambica machines 🙂

Blue pieces -2

Finally a dark enough blue with pigment less Pu 230. Should be ready to demould in 2.5 hours. Got 10kgs of Pu without pigment thanks to veeyor and Ola uncle.

This was 150 Pu + 50 hardener plus 2 g of blue. I need almost 240 ml for the entire set. Put the set on top of my cooler for 15 minutes hoping the vibrations would release any bubbles. (thanks for the suggestion v) .

Cover sketch

Sud and I discussed the cover page today

Cutting die – tile base

Blue pieces

Beginning the blue. 1:4 hardener to white with 0.6 g of blue in 200 ml.

Finishing the pieces – sanding

Some unanticipated problems from sanding plastics. Just one of those days!

Yellow

More like rubber. Less like plastic 😦 . 2 g of yellow in 165+55g of pu